Our Products

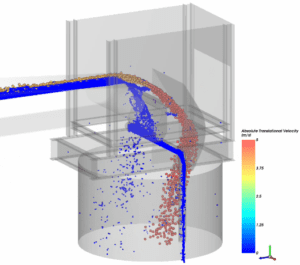

Transfer Chutes

MCFT has successfully provided more than 100 transfer chutes in the last 10 years for our clients throughout Asia and Australia. The application industries include mining, iron-steel, port, power plant and food. MCFT is committed to operate at the forefront of materials handling technology and constantly improving our designs to keep up with industry standards and their unique requirements.

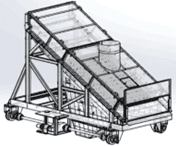

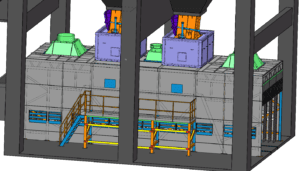

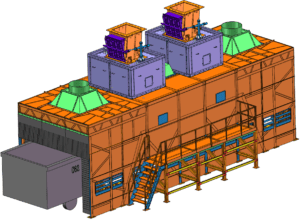

Screens

MCFT has developed a sliding screen (patent applied) to replace the existing vibrating screen for the bulk material with good flowability such as coke. Compared to the vibrating screen, MCFT’s sliding screen has the following advantages:

- Without power energy cost

- Extended screen service life

- Higher screen efficiency (>90%)

- Quickly adjust the distance/gap between screen bars

- Minimized bulk material degradation

- Lower dust generation & noise

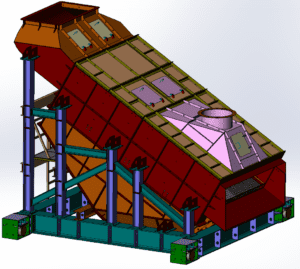

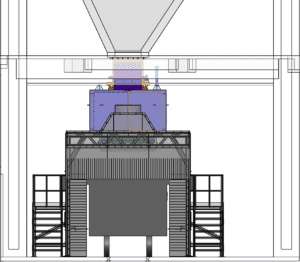

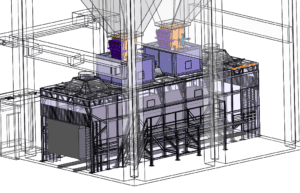

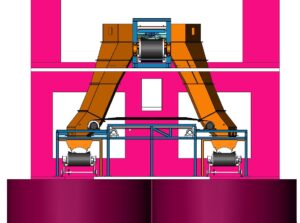

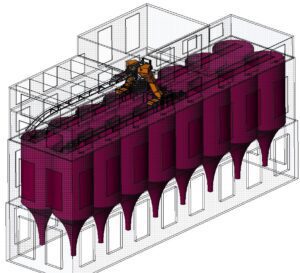

Train/Truck Loadout

The benefits realized by implementing MCFT’s automated or continuous load-out system:

- Minimizes loading time

- Consistently and accurately loads every railcar with target weight

- Automated load adjustment, according to the condition of each car

- Full car utilization without the risk of overfilling

- Minimized dust generation

- Lower annual transportation cost

- Enhances safety as there is no need for personnel to work in the loading area

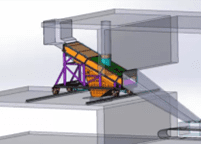

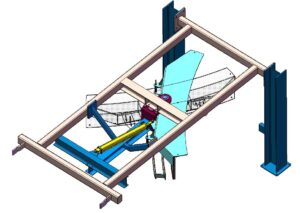

Diverter Plows

Compared to other solutions, a diverter plow is a relatively low cost option to design, manufacture and install. It can be designed to fit onto any conveyor with little modification done to the existing structure. While it is not typically designed into a new conveyor system, it rather becomes a necessity as the requirements of a bulk materials plant changes.

The illustrated example is to design a diverter plow to make the short shuttle conveyor redundant. The diversion plow can remove all the coal from the feeding conveyor and create a secondary circuit, which consists of adjustable wear-resistant blade (double) and belt support mechanism.