MCFT Sliding Screen Factsheet

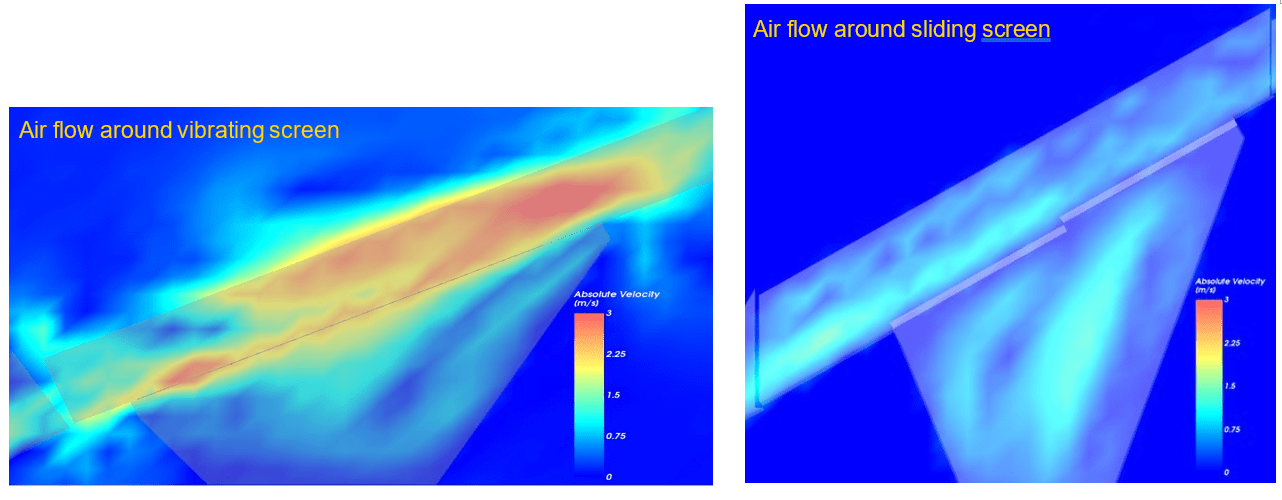

To replace the traditional vibrating screens, the sliding screen for coke is invented & applied to reduce energy consumption and environment impact

Components:

- Inlet/transition chute

- Screen bars with ceramic tile liner

- Fines hopper

- Rail travel mechanism

- Supports

- Outlet transfer chute

- Dust pipe collector interface (reserved)

Advantages:

◆ Energy saving – No vibrating power

◆ Small size & Light weight -↓30%

◆ Avoid resonance

◆ High screening efficiency – >90%

◆ Long service life – >8 years

◆ Screen-bar gap adjustability – 3~5 Hours

◆ Low dust emission – ↓85%

◆ Low noise decibel – 40~45dB(A) ↓60%

◆ Low particle attrition – ↓1.32% (coke breeze)

Applications:

◇Dry Quenching Coke

◇Max. working temperature: 250℃

◇Min. screening particle size: 5mm

◇Max. capacity: 800tph

◇Lump size: <300mm

Coke Degradation (particle size distribution)

For more information about MCFT, please visit MCFT ENGINEERING SERVICES PTY LTD.

Unit 1, 27-29 New Dapto Road, Wollongong, NSW, Australia, 2500

Ph: (+61) 425 133 848 || email: michael.fei@mcft.com.au || ABN 37 669 406 213